More

Purpose/Impact

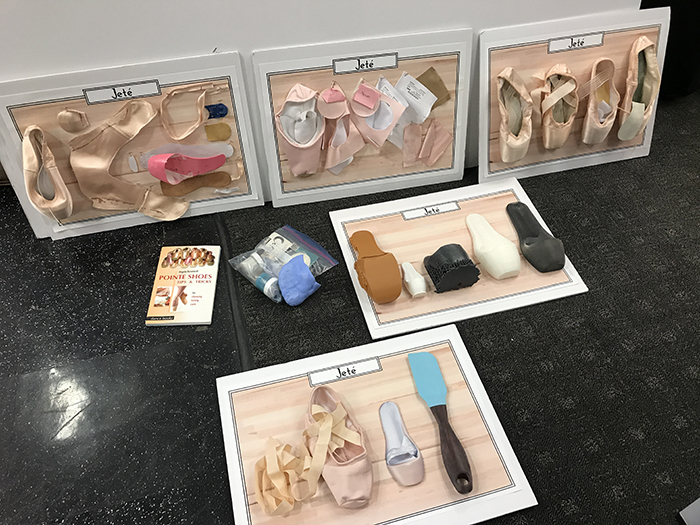

The current ballerina slipper is made primarily with the same materials that were used when the concept of a pointe shoe was first introduced—nails, glue, burlap, satin, cardboard, canvas, and leather. Thus, the limitations of the original slippers persist to this day:

- The shoes have a short lifespan because of the wear and tear on the shoe’s satin. Once the satin becomes worn, the shoe is unusable.

- The ribbons that lace the shoes together are sold separately. This requires the ballerina to hand sew all ribbons.

- Breaking in a shoe is time-consuming and can be painful.

- As the bones in the foot grow, the shoe must be refitted to ensure adequate support. Failure to have the proper fit will result in bunions and other orthopedic deformities.

- At an average of $82 per pair, buying these shoes is a financial hardship to the typical dancer. cardboard

Outcomes/Accomplishments

Cannon and Pushkarewicz redesigned the shoe with a removable satin slipper and a custom 3D-printed toe box and shank structure, dramatically extending the shoe’s life and improving its performance. The 3D-printed toe box matches the dancer’s foot shape with an antimicrobial finish that further enhances durability.

Status Update

By leveraging the social influencer market for dancers, the inventors are planning to establish a relationship with Chloe Lukasiak, a dance influencer with over 6 million Instagram followers. Additionally, the shoe will be distributed at summer intensive dance programs. The inventors are currently exploring options for production and seed financing.